ECS - Electronically Controlled Suspension

The main purpose of the ECS is to adapt the suspension of the car into the driving conditions taking account the speed, surface of the road, cornering, stopping requirements and acceleration. The aim is to increase safety and driving comfort. The basic driving characteristics of the car can be changed from a soft, smooth ride to a hard driving experience of a sports car and everything between. All should happen quickly and continuously. The driver has an option for select for manual selection by pushing a button to drive continuously in sport, normal or comfort mode.

The purpose of an accelerometer is to measure the car body motion and, in some cases, the vertical motion of the front wheels. The car body motion is measured by two accelerometers located very close to the upper fixing point of the front shock absorbers and springs. The wheel hub sensors are located at the other end of the shocks and springs next to the wheel. The idea is to measure the difference in vertical motion between the wheel and the body. In more modern systems the wheel hub sensors have been replaced by position sensors, which directly measure the distance between the wheel and body.

Most systems also include one accelerometer in the middle or rear part of the car's to measure pitch of the car. The aim of this feature is to reduce the inclination of the car when accelerating and braking.

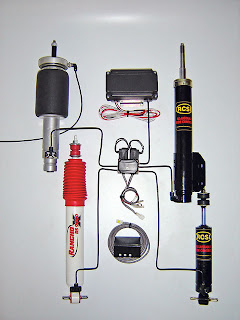

Today the majority of new cars in the luxury and upper middle class range, including some Sport Utility Vehicles (SUVs), have air suspension. The volume of the air in the air cushions in all corners of the car can be controlled. This is done by controlling the flow of the air in and out of the additional air reservoirs. The system includes a special air compressor, one or two air reservoirs, four shock absorber units with air springs and traditional shock absorbers, 2 to 5 stand-alone accelerometers and the electronic control unit (ECU).

The alternative solution is to control the flow of oil inside traditional shock absorbers. The flow of oil is controlled by special electrically controlled valves inside the shock absorber. The system contains 3 or 5 stand alone accelerometers.

Active suspension

The active suspension and adaptive suspension/semi-active suspension are types of automotive suspensions that controls the vertical movement of the wheels with an onboard system, rather than in passive suspensions where the movement is being determined entirely by the road surface.

This technology allows car manufacturers to achieve a greater degree of ride quality and car handling by keeping the tires perpendicular to the road in corners, allowing better traction and control. An onboard computer detects body movement from sensors throughout the vehicle and, using data calculated by opportune control techniques, controls the action of the active and semi-active suspensions. The system virtually eliminates body roll and pitch variation in many driving situations including cornering, accelerating, andbraking.

Active suspensions can be generally divided into two main classes: pure active suspensions and adaptive/semi-active suspensions. While adaptive suspensions only vary shock absorber firmness to match changing road or dynamic conditions, active suspensions uses some type of actuator to literally raise and lower the chassis independently at each wheel.

Manufacturer brand names for adaptive suspensions include Airmatic suspension (Mercedes-Benz), Adaptive Damping, and Road-Sensing Suspension. Active suspensions include Active Body Control (Mercedes-Benz) and Active Roll Stabilization (BMW). For instance, in the 2005 model year, the Mercedes-Benz S55 AMG has the Active Body Control active suspension as standard equipment, while the Mercedes-Benz S430 comes with the Airmatic adaptive suspension and has Active Body Control as an option.According to The Truth About Cars, Active Body Control (ABC) "senses body movement and strangles it at birth. The PRE-ALPHABETIZED electro-hydraulic doohickey makes a 4300lbs. sports sedan handle like a 3000lbs. sports sedan"

Active

Active suspensions, the first to be introduced, use separate actuators which can exert an independent force on the suspension to improve the riding characteristics. The drawbacks of this design (at least today) are high cost, added complication/mass of the apparatus, and the need for rather frequent maintenance on some implementations. Maintenance can be problematic, since only a factory-authorized dealer will have the tools and mechanics with knowledge of the system, and some problems can be difficult to diagnose.

Michelin's Active Wheel incorporates an in-wheel electrical suspension motor that controls torque distribution, traction, turning maneuvers, pitch, roll and suspension damping for that wheel, in addition to an in-wheel electric traction motor.

Hydraulic actuated

Hydraulically actuated suspensions are controlled with the use of hydraulic servomechanisms. The hydraulic pressure to the servos is supplied by a high pressure radial piston hydraulic pump. Sensors continually monitor body movement and vehicle ride level, constantly supplying the computer with new data. As the computer receives and processes data, it operates the hydraulic servos, mounted beside each wheel. Almost instantly, the servo-regulated suspension generates counter forces to body lean, dive, and squat during driving maneuvers.

In practice, the system has always incorporated the desirable self-levelling suspension and height adjustable suspension features, with the latter now tied to vehicle speed for improved aerodynamic performance, as the vehicle lowers itself at high speed.

Colin Chapman developed the original concept of computer management of hydraulic suspension in the 1980s to improve cornering in racing cars. Lotus developed a version of its 1985 Excel with electro-hydraulic active suspension, but never offered it for sale.

Computer Active Technology Suspension (CATS) co-ordinates the best possible balance between ride quality and handling by analysing road conditions and making up to 3,000 adjustments every second to the suspension settings via electronically controlled dampers.

Electromagnetic recuperative

This type of active suspension uses linear electromagnetic motors attached to each wheel. It provides extremely fast response, and allows regeneration of power consumed by utilizing the motors as generators. This nearly surmounts the issues of slow response times and high power consumption of hydraulic systems. It has only recently come to light as a proof of concept model from the Bose company, the founder of which has been working on exotic suspensions for many years while he worked as an MIT professor. Electronically controlled active suspension system (ECASS) technology was patented by the University of Texas Center for Electromechanics in the 1990s and has been developed by L-3 Electronic Systems for use on military vehicles. The ECASS-equipped HMMWV exceeded the performance specifications for all performance evaluations in terms of absorbed power to the vehicle operator, stability and handling.

Adaptive/Semi-active

Adaptive/semi-active systems can only change the viscous damping coefficient of the shock absorber, and do not add energy to the suspension system. Though limited in their intervention (for example, the control force can never have different direction than the current vector of velocity of the suspension), semi-active suspensions are less expensive to design and consume far less energy. In recent times, research in semi-active suspensions has continued to advance with respect to their capabilities, narrowing the gap between semi-active and fully active suspension systems.

Solenoid/valve actuated

This type is the most economic and basic type of semi-active suspensions. They consist of a solenoid valve which alters the flow of the hydraulic medium inside the shock absorber, therefore changing the damping characteristics of the suspension setup. The solenoids are wired to the controlling computer, which sends them commands depending on the control algorithm (usually the so-called "Sky-Hook" technique). This type of system used in Cadillac's Computer Command Ride (CCR) suspension system.

Magneto rheological damper

Another fairly recent method incorporates magneto rheological dampers with a brand name MagneRide. It was initially developed by Delphi Corporation for GM and was standard, as many other new technologies, for Cadillac Seville STS (from model 2002), and on some other GM models from 2003. This was an upgrade for semi-active systems ("automatic road-sensing suspensions") used in upscale GM vehicles for decades. It allows, together with faster modern computers, changing the stiffness of all wheel suspensions independently. These dampers are finding increased usage in the US and already leases to some foreign brands, mostly in more expensive vehicles. In this system, being in development for 25 years, the damper fluid contains metallic particles. Through the onboard computer, the dampers' compliance characteristics are controlled by an electromagnet. Essentially, increasing the current flow into the damper raises the compression/rebound rates, while a decrease softens the effect of the dampers. Information from wheel sensors (about suspension extension), steering, acceleration sensors and some others is used to calculate the optimized stiffness. The fast reaction of the system allows, for instance, make softer passing by a single wheel over a bump in the road.

.jpg)

I found your blog when I was looking for a different sort of information but I was very happy and glad to read through your blog. The information available here is great.

ReplyDeleteI know something information, to know you can click here

auto mechanic Brisbane

Car Services Brisbane